Find out why adding new technology for technology’s sake is not the answer to solving your supply chain planning. And how integrated digital planning could be.

For many organizations, the promise of new technology and digital holds great appeal. However, leveraging technology alone is not sufficient to set you up in the digital journey of creating an integrated planning capability. The real test is linking your strategic, tactical and operational planning horizons as well as removing the silos across your organization to make gains in agility and efficiency. But all of this is easier said than done.

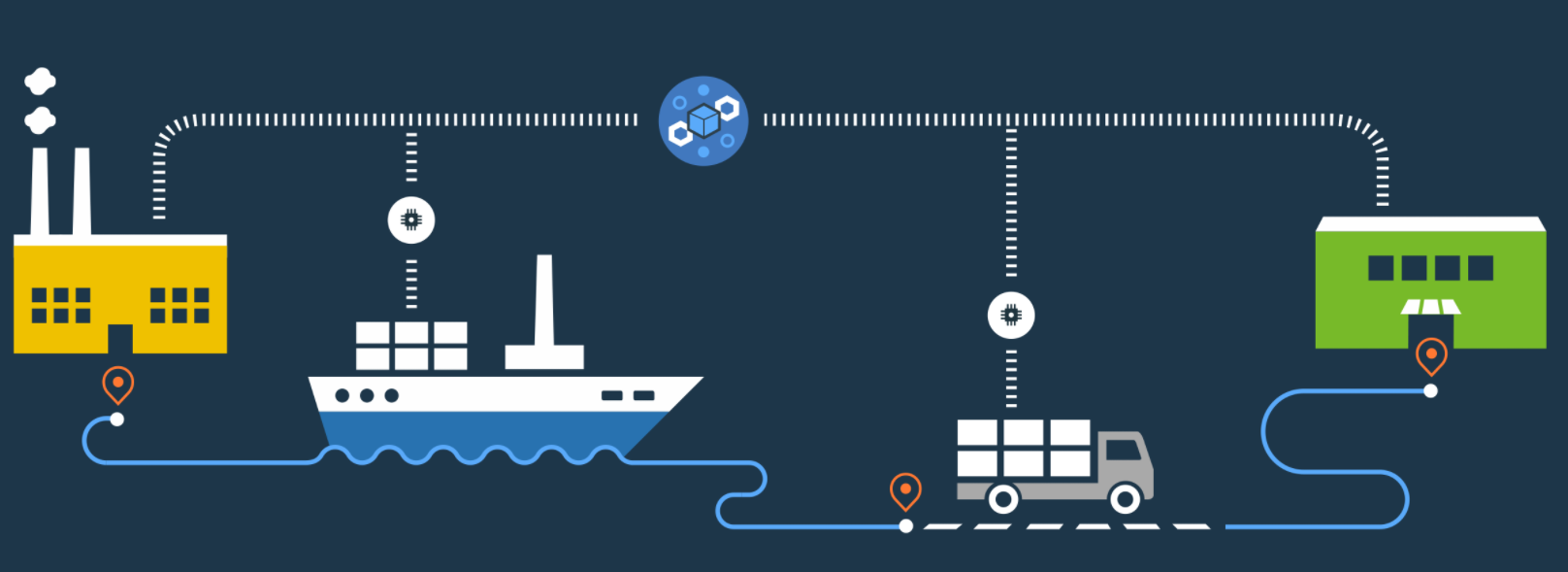

The ultimate prize is for companies to know what has been sold today so that they can make more of it tomorrow and restock shelves in three to four days’ time. Products flowing seamlessly direct to retailers’ shelves in line with consumption … this is the dream, and integrated digital planning is the reality.

Integrated digital planning is a comprehensive concept for successfully and sensibly achieving horizontal and vertical planning automation. Every company can get there, and the journey has five steps:

- Planning hubs and centres of excellence

A multifunctional synchronization centre of excellence can enable true end-to-end synchronization.

- Transform sales and operations planning to integrated digital planning, and then to enterprise business planning

The set of processes, collaboration across functions, governance and cadence is required for driving profitable growth in a transparent and insightful way.

- Segment and synchronize – create flow across the segmented value chain

Remove the bullwhip effect in your supply chain, and bring stability across your supply chain to flow your product to the market.

- Establish a connected and exception-based value chain to focus planning efforts and gain efficiencies

Leverage stability, optimize your planning processes and technology and deliver an exception-based planning value chain.

Establish “lights out” planning with intelligent automation based on cognitive and artificial intelligence (AI) and robotic process automation

- Create an autonomous planning capability that will take care of the best part of your planning effort, giving time to planners to monitor the value chain and make better decisions to support the business in line with the other functions

There are no technology shortcuts

We work with many clients who come to us because they are anxious about the digitalization trend. They don’t want to miss the bus and do want to know how they can implement the latest technology into their supply chain. This is the wrong approach. There are no shortcuts, and adding new technology for technology’s sake won’t solve all existing problems

Yet, time and again we see the same problems at client organizations — badly implemented processes, unclear roles and responsibilities and organizational setup, to name just a few — and these need to be fixed before the journey to digital can start.

Data quality is a widespread problem, too. Clean master data is essential for automation, but legacy ERPs and mismatched systems can make it incoherent. The one exception to this is the possibility of using AI in the data lake to match up product numbers and descriptions across multiple databases. But getting clean, quality data takes time as well. There are no quick fixes.

Detours on the way to integrated digital planning

The biggest issues we see in planning are non-synchronization and a persistent bullwhip effect across the value chain. Often we find a company has very high inventory but, at the same time, is wrestling with stockouts and service level issues. But they are not able to explain why this is happening.

In our experience, this challenge comes from a variety of root causes:

- High forecast bias and/or error

- Disconnect with sales and marketing activities that drive demand

- A lack of segmentation and specific planning parameters by product, still in a one-size-fits-all mentality

- Connection to consumer demand not managed — the supply chain is not set to react to true demand — only to forecast change

- Key suppliers not integrated into the planning capability — their unreliability affects your production upstream

If the hard work of these issues, such as breaking down silos, streamlining processes and improving data quality, has not been done, the journey to integrated digital planning will be that much harder.