3 Areas of Technological Innovation in Warehousing and Distribution Management:

In today’s fast-paced global markets, warehousing and distribution companies, like in all other industries, are being disrupted by the relentless march of technology – all are eager to gain the competitive edge by optimising, mechanising and automating the supply chain in order to cut warehousing and distribution costs and increase efficiency. The supply chain of the future will be very different from the one in which warehousing and distribution companies operate today.

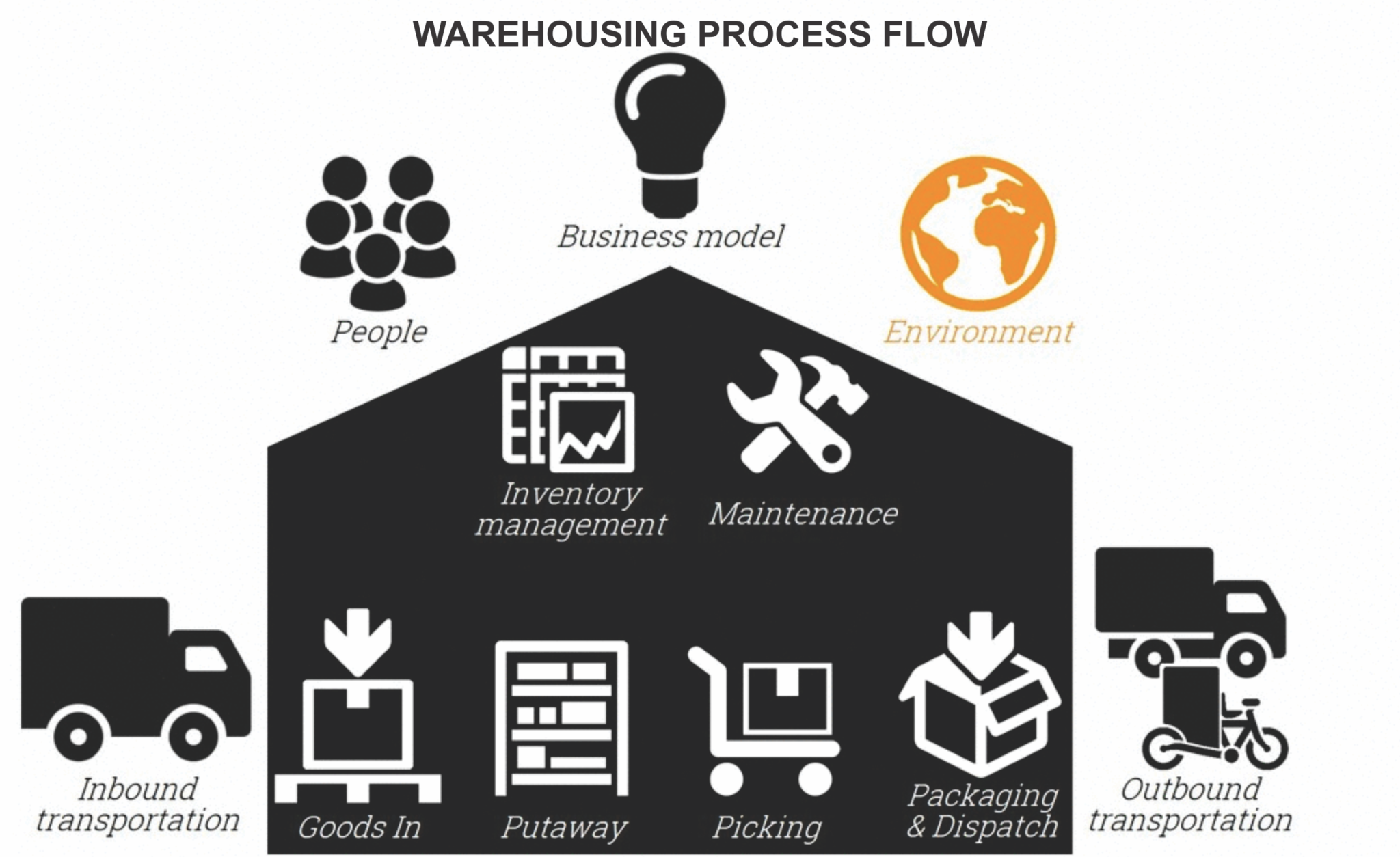

Here are some key changes taking place in the field of logistics, warehousing and distribution:

NWCC identified nine of the most promising features that will make the largest impact on warehouse efficiency:

1) Wireless technology and real-time inventory tracking: Warehouse operators are adopting new technologies to build efficiency into every aspect of the warehouse. Radio frequency identification (RFID) tags attached to each inventory item can transmit real-time data to and from the warehouse floor and inventory management applications, allowing warehouse teams to use mobile devices to track inventory from the moment it arrives.

2) A hyper-connected facility: In a hyper-connected warehouse, operating systems are laid out in a highly advanced matrix to accommodate the growing mix of technologies. Today’s warehouses hold bandwidth for technologies like barcoding, IoT, RFID scanning, GPS, load optimization and future technology innovations that may emerge. With this tech in place, logistics managers can quickly make and execute decisions.

3) The new forklift: Forklifts, always a familiar sight in warehouses, are more connected than ever. IoT technologies can connect a warehouse operator’s forklifts with their enterprise resource planning system and workers across the warehouse, shaving operations time. Some forklift manufacturers are incorporating alternative fuel systems and energy-efficient engines to reduce energy costs.

4) Growing clear heights: To optimize warehouse utilization, yesterday’s 24- to 26-foot ceiling height has risen to the 36- to the 40-foot range today. One reason is that automated picking technology can easily reach even the highest shelves. Another is that today’s lighting systems can efficiently illuminate tall spaces. Yet a third factor is the availability of fire-suppression technologies that can reach higher ceilings.

5) Picking tech, picking up speed: From multilingual voice-picking and augmented reality to specialized robots, revolutionary technologies are changing picking practices. These technologies enable logistics operators to expand their labour pools by overcoming language barriers and accommodating a range of skillsets.

6) Sustainability, making strides: Alternative energy and energy efficiency are no longer optional as warehouse operators bring more automation into the warehouse. Solar panels, LED lighting, cool-roof systems, thermal glass, clerestory windows and other new green materials and innovations are leading warehouses into a new age.

7) Human-centric design: As labour shortages rise in many markets, there is growing importance on workers’ quality of life in the warehouse. New features such as efficient lighting, air quality sensors and temperature control are more common as design becomes more human-centric. Improving the working environment not only benefits employee health but also reduces employee turnover and facilities risks.

8) When it comes to land, flexibility is the name of the game: Industrial tenants are demanding flexibility in response to highly variable business conditions. Tenants want the option to add land and space if additional needs arise, like a seasonal rush. “Flex land” could be deployed for needs such as additional truck storage or warehouse expansion.

9) Super-flat to sloped floors: The super-flat floor has long been the norm in warehouses. Although many warehouse operators continue to require exceptionally flat floors for highly precise robotic picking and racking technology, sloped floors are appearing to accommodate technologies for moving inbound and outbound shipments. Tracking and Reporting Making decisions based on out-dated information and vague estimations is soon to become a thing of the past in any business, including warehousing and distribution companies.

With satellite and other forms of tracking being utilised in all stages of the warehousing and distribution supply chain, real-time tracking of cargo from origin to destination is bound to become commonplace in the future.

These technologies include RFIDs, GPS tracking, geo-fencing, zone control and smart meters. With the abundance of new information available, the supply chain manager has far more intelligence upon which to base his decision, leading to a smoother experience overall, as well as lower costs and increased speed of delivery.

Manufacturing

In school, we all learned how the first industrial revolution, immoraltalised by Henry Ford’s Model T production line, was the birth of large scale mass production as we know it. Many forecasts that an equally ground-breaking industrial revolution is taking place today.

Robotics, 3D printing and other incredible technologies are achieving feats of production never before imagined, and are being used more and more commonly in the manufacturing industry around the world.

The cost and time it takes to prototype and produces a product can essentially be halved by injecting a little technology into the process. Manufacturing is also become more and more competitively priced as these technologies become more mainstream.

This will doubtless have a huge impact on the supply chain in the near future – after all, if a robot can be shipped overseas and produce a perfect product anywhere you care to plug it in, what need is there for large scale shipping at all?

Eco-friendliness

The world economy and the Earth’s ecology are both under severe strain, but technology is a shining light of hope on the horizon – able to reduce man’s harmful effects on the planet and drive savings for warehousing and distribution companies at the same time.

Many factories and warehouses now run either partially or entirely on green technologies such as solar power, and the possibility of fleets of electric trucks transporting the world’s cargo is fast becoming a reality.

Unlike many of our competitors, our scale means we deploy a large number of these systems in any given year, you benefit therefore from this unrivalled experience and expertise.

Get in touch at [email protected] or call us at 1800 123 4855